Multifunctional waterproof coating single-component is a kind of polymer liquid reaction curing elastic waterproof coating. The product is solvent-free, non-toxic, tasteless, and has good adhesion. It has strong adhesion to cement or concrete base, stone and metal products. The product has stable chemical properties, long-term UV resistance, high strength, high elongation, good elasticity and good waterproof effect. A compact, firm and flexible waterproof coating film is formed on the base surface, with high tensile strength and excellent extensibility. This product has excellent elasticity, outstanding outdoor durability and anti-ultraviolet performance, especially suitable for roofing and directly exposed waterproof projects.

Features

1. It can be used immediately after opening the cover, the construction is safe and simple, and the construction period is short.

2. It can be constructed on the base surface that is wet but without clear water, with strong adhesion to the base and wide adaptability to the base surface.

3. It has strong adhesion to concrete, masonry, mortar, metal, wood, plastic, insulation layer, steel structure, etc.

4. Xu film has high tensile strength, large extensibility, good integrity of the waterproof layer, and strong ability to adapt to the cracking and deformation of the base layer.

5. Excellent cold resistance, corrosion resistance and aging resistance.

6. Super adhesion, high solid content, less dosage per unit area, and high cost performance.

7. Super anti-aging and anti-ultraviolet, especially suitable for steel structure roof and directly exposed waterproof projects.

Precautions

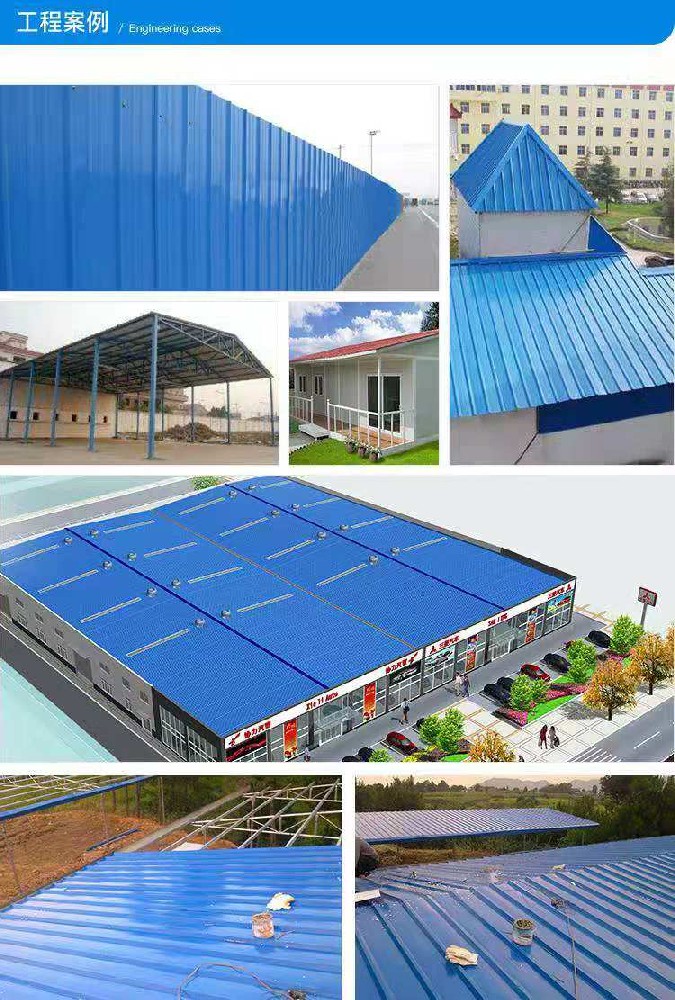

Widely used in old and new waterproof projects: waterproof and moisture-proof for roofs, color steel tiles, basements, tunnels, bridges, civil air defense and other projects, and can also be used for anti-corrosion projects such as metal pipes, workshop floors, pools, etc.; roofs, exterior walls and planted roofs Directly exposed waterproofing works. Waterproof sealing of bathroom, kitchen, balcony, window sill seam. All kinds of color steel seams and large-span canopy waterproof. Waterproof sealing of various pools, underground fire pools, sewage treatment and crack repair with poor ventilation conditions, expansion joints, separation joints, etc.

Construction method

The base surface is required to be flat and compact, free of oil, no sand, and no clear water. If there are cracks in the base layer, it should be repaired first, and the yin and yang corners, deformation joints and other parts should be strengthened. The metal surface needs to be derusted, polished, and pre-coated with a layer of anti-corrosion and anti-rust treatment agent. Use a scraper or roller brush to apply the paint evenly on the base surface, and there should be no side brushing, bulging, delamination, etc. The drying time of the coating is about 10 hours at room temperature. The interval between each brushing is not subject to stickiness. Generally, 2-3 brushes are applied. The recommended dosage is 2KG/m2, and the thickness is about 1.2mm.